BMC ( Bulk Moldıng Compound )

BMC ( BULK MOLDING COMPOUND )

It is a bulk shaped hot press molding compound formed by kneading a thermosetting resin matrix containing chopped glass fiber as reinforcement material, filler and additives in a Z-Blade machine.

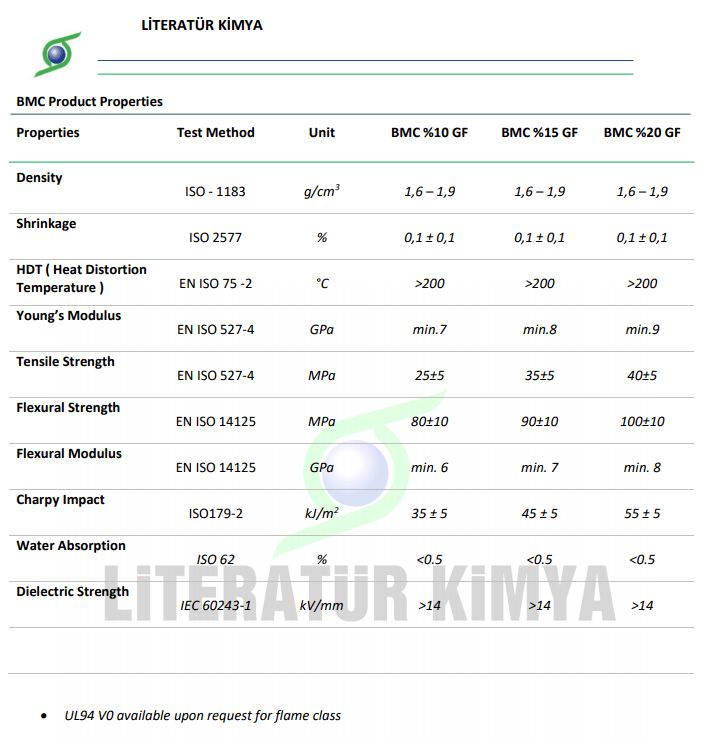

Depending on the finished product specifications, BMC is produced with the chopped glass fiber 3 - 6 - 12 mm lengths and the fiber amount of the total weight is % 10 – 25. BMC is molded at under pressure with heat and the final composite product becomes a material with low water absorption, high chemical resistance, high mechanical strength and lighter than metal.

BMC storage temperatures should be 18°C - 25°C. Shelf life varies between 1 and 3 months. In addition, the shelf life of the product decreases at temperatures higher than the storage specification.

Bulk Molding Compound (BMC) is a fully integrated dough ready for molding, combining reinforcement materials, resin, fillers, catalysts, mold release agents, and other additives to extend shelf life. BMC is designed by our R&D team depending on product expectations, can be designed according to the desired RAL code, flame retardancy class, fiber ratio, and UV resistance.

As molding time, pressure, and temperature vary according to part dimensions and BMC content, technical support is provided to our customers for molding.

BMC is packaged in vacuum PE-PA bags with low gas permeability in the desired quantity and then passed through a metal detector and shipped in recycled case or carton boxes.

Our company has a production capacity of 1,000 tons of BMC per month with four Z-Blade equipped with automatic dosing system.

Why BMC?

• Low Specific Gravity, Lightweight

• Dimensional Stability

• High Surface Quality

• High Mechanical Performance

• High Weather Resistance

• High Thermal Resistance

• High Chemical Resistance

• Easy Machinability

• Low Water Absorption

• Suitable for Metal Inserts

• High Corrosion Resistance

• Electrical Insulation

• Low Cost

• Design Flexibility for Complex Shapes

• Self-coloring Capability

• Flame Retardant Properties with Flame Retardant Additives

• Sanding and Painting Capability

APPLICATION AREAS

Automotive Sector: BMC is widely used in the production of automotive headlamps housings.

Electrical and Electronic Industry: BMC is commonly preferred for the production of parts for electrical devices and electrical panels. It is suitable for parts requiring electrical insulation due to its high dielectric properties.

Construction Sector: BMC can be preferred for construction concrete molds, rain channels and rainwater grates.

BMC is preferable.